|

| September 18, 2018 | Volume 14 Issue 35 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Motors for model train meet demanding requirements

Custom micro-drive provides realistic motion and control experience.

Steam engines and model train sets are classic model-making applications. In the distant past, these items were roughly molded from tin; today fine detail is called for. But it's not always all about appearance. For modern model-train engineers, the focus is increasingly on realistic handling. Today's electronics allow a large number of locomotives to be controlled digitally with no complex wiring or different power supplies. A micro-drive in the model locomotive provides the link between the electronics and the mechanisms, enabling delicate shunting (car-switching) operations and inter-urban journeys with many cars to be replicated accurately to scale.

These days, model train sets are popular with adults and children alike. Depending on the use, a wide array of toy trains and exceptionally faithful replica models is available. As one of the leading providers of high-end model train systems, Nuremberg, Germany-based Fleischmann's 2.28-in. (57.8-mm) miniature replica in N gauge of the Bavarian 70 series locomotive (BR 70) from 1930 is both convincing and highly detailed. Even the lettering, measuring just tenths of a millimeter high, can be read perfectly with a magnifying glass. Naturally, this passion for perfection does not stop when it comes to the drive technology. Major strides have been made in the development of this locomotive, with the professional model makers at Fleischmann bringing micro-drive specialist FAULHABER into the engineering pool to help execute a concept that meticulously considered drive requirements, model size, and performance characteristics right from the start.

A small locomotive that makes a big impression

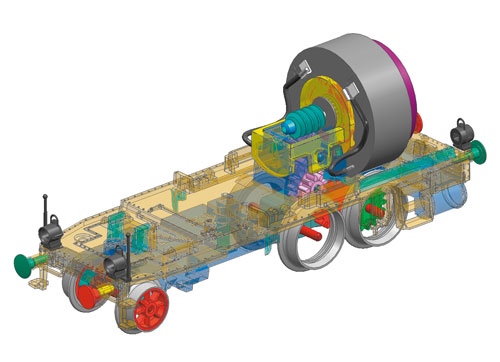

Building a model-train system on the scale of 1:160 (N gauge) involves working with very small units. In this case, the BR 70 locomotive in N gauge is just over 2.25 in. when measured buffer to buffer. Weight is also low at just 1.27 oz (36 g). It is, nevertheless, essential that every detail is accurate and that the model's driving performance is appropriate and realistic. The locomotive's undercarriage and body are die-cast in metal with added plastic parts. This allows even the smallest details to be faithfully replicated in series production. To match the original, realistic lights are integrated using tiny, warm-white LEDs. The lighting switches to the direction of travel automatically.

When it comes to the drive design, certain mechanical and physical conditions needed to be considered. As on large locomotives, traction (and, on this model, power transmission) between the wheel and the track is a crucial factor. A small motor generates only low torque, but it requires a high engine speed. The engine speed must then be geared down relative to the model scale and the size of the drive wheels. Other electronic components can transmit digital control signals to the drive or lights and auxiliary equipment, for example. All this must function reliably out of sight for many years while taking up minimal space.

High-performing micro drives

In the case of the BR 70 model locomotive, with a weight of just over 1 oz and a relatively high engine speed, quiet running is a particular issue. Even the slightest imbalance in the rotor on this lightweight locomotive will cause vibrations and possible resonance within the model railway system on which the rails are laid. This issue was resolved by deploying a high-precision flywheel on the motor shaft. Flywheel wobble is just 0.03 mm.

Thanks to this exacting design, the motor and flywheel are as large as the locomotive body permits. The advantage of this approach is that the large flywheel, which stores kinetic energy, delivers excellent running performance over points and sets of points, even during very slow shunting operations. This is particularly important when there are brief interruptions in the power supply from the track.

A version of this locomotive with an integrated digital decoder is specially adapted to the drive motor to make the slowest movements appear more realistic. Effortlessly absorbing the axial forces of the first worm-gearing stage, the motor's durable, lifetime-lubricated bearings enhance this micro-drive, which has been optimized for model-making.

Modern micro-drives can be customized for virtually any deployment scenario. The sooner drive specialists are involved in developing an application, the smoother the process of integrating the drive. In this way, specific key characteristics, such as special configurations, short-term overloading, extremely quiet running, etc., can mostly be achieved with ease.

Although ready-made drives meet many requirements, for high-end and specialized applications, customization is the answer. Micro-drives are no longer limited by technology. Instead, it is up to developers to find new creative possibilities, not just in model-making.

About MICROMO solutions

DC motors from the FAULHABER Group are available in the U.S. through MICROMO (Clearwater, FL). Learn more about MICROMO's micro-motion solutions at www.MICROMO.com.

Published September 2018

Rate this article

View our terms of use and privacy policy